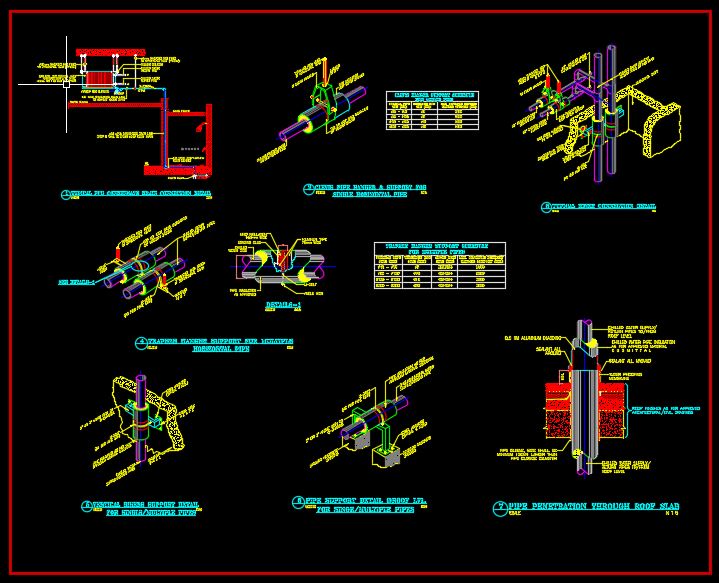

Chilled Water Piping Detail Autocad Free Drawing

13 December 2019Table of Contents

Chilled Water Piping Detail Autocad Free Drawing

Chilled water piping systems play a critical role in modern HVAC (Heating, Ventilation, and Air Conditioning) applications, especially in large commercial buildings, hospitals, data centers, and industrial facilities. These systems are designed to efficiently distribute chilled water to air handling units or fan coil units, where it absorbs heat from the building’s interior, providing reliable and energy-efficient cooling.

In this article, we’ll break down what chilled water piping systems are, how they work, key components, design considerations, and the benefits they offer.

What Is a Chilled Water Piping System?

A chilled water piping system is a network of insulated pipes that circulate cooled water from a central chiller to various parts of a building. The water absorbs heat from the indoor environment and returns to the chiller to be cooled again. This closed-loop system is common in medium to large buildings where traditional air-cooled systems are inefficient.

Key Components of a Chilled Water Piping System

-

Chillers

These machines remove heat from the water using either vapor-compression or absorption refrigeration cycles. The chilled water typically leaves the chiller at around 4–7°C (39–45°F). -

Pumps

Pumps circulate the chilled water through the system, ensuring it reaches all necessary zones of the building. -

Piping Network

Pipes, usually made from steel, copper, or PEX, transport the chilled water. They must be properly insulated to prevent condensation and energy loss. -

Control Valves

These regulate flow rates and help maintain consistent temperatures throughout the system. -

Air Handling Units (AHUs) and Fan Coil Units (FCUs)

These are the terminal devices that extract heat from the air using the chilled water. -

Expansion Tanks and Air Separators

These components maintain pressure stability and remove air bubbles from the system.

Types of Chilled Water Piping Layouts

-

Direct Return System: The water returns to the chiller via the shortest path. This system is simpler but may lead to imbalanced flow rates.

-

Reverse Return System: All circuits are the same length, ensuring balanced water flow and consistent performance.

-

Primary-Secondary Systems: Separate pumping loops reduce hydraulic conflicts and improve energy efficiency.

Chilled Water Piping Design Considerations

-

Pipe Sizing: Correct sizing minimizes pressure drops and ensures efficient flow.

-

Insulation: Prevents condensation and reduces thermal losses.

-

Material Selection: Choose corrosion-resistant and pressure-rated materials based on the building’s requirements.

-

Flow Control: Incorporate variable speed pumps and automated control valves for better energy performance.

-

Accessibility: Pipes should be accessible for maintenance without disrupting building operations.

Advantages of Chilled Water Piping Systems

-

Energy Efficiency

Centralized cooling and water’s high thermal capacity make these systems more efficient than air-based systems. -

Scalability

Easy to expand as building needs grow. -

Quiet Operation

Reduced mechanical noise compared to distributed systems. -

Space Saving

Smaller ductwork is needed since chilled water carries heat more effectively than air. -

Better Control

Fine-tuned temperature control in different zones of a building.

Common Applications

-

High-rise commercial buildings

-

Hospitals and healthcare facilities

-

Data centers

-

Universities and campus environments

-

Manufacturing and industrial plants

Maintenance and Troubleshooting Tips

-

Regular Inspections: Check for leaks, corrosion, and insulation damage.

-

Flush System Periodically: Remove sediment and biofilm buildup.

-

Monitor Water Quality: Prevent scale and microbial growth.

-

Calibrate Controls: Ensure optimal temperature and flow settings.

To download more free Autocad templates you can visit www.cadtemplates.org