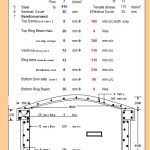

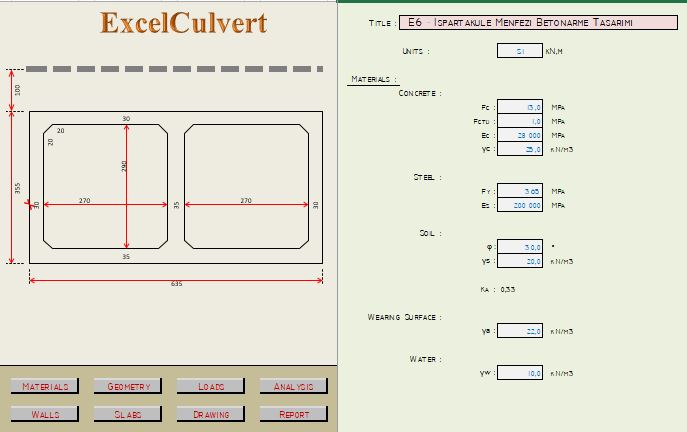

Concrete Box Culvert analysis and Design Spreadsheet

4 January 2018Table of Contents

Concrete Box Culvert analysis and Design Spreadsheet

What Is a Concrete Box Culvert?

A concrete box culvert is a four-sided, rectangular-shaped structure used primarily to convey water beneath roads, railways, or embankments. These culverts are a cornerstone of civil engineering, providing reliable drainage while maintaining the integrity of infrastructure.

Built from reinforced concrete, box culverts are designed to handle heavy loads, resist erosion, and adapt to a wide range of soil and water conditions.

Why Choose Concrete Box Culverts?

1. Durability That Lasts Decades

Concrete box culverts are incredibly robust. With proper design and installation, they can last 75–100 years with minimal maintenance. Their resistance to rust, rot, and fire makes them ideal for long-term projects.

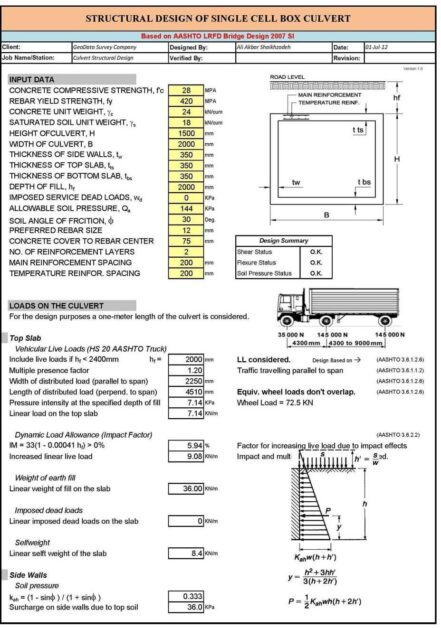

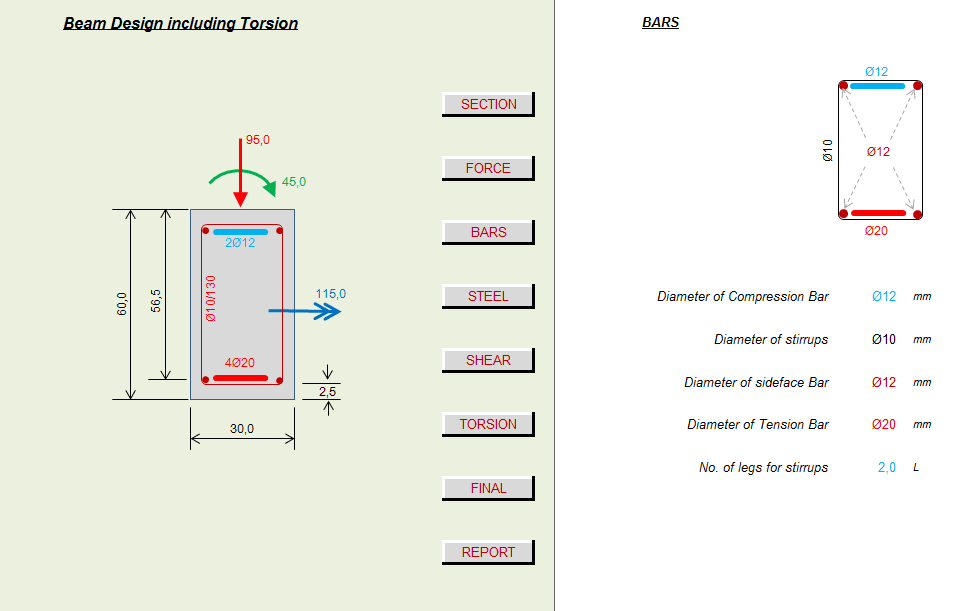

2. High Load Capacity

Thanks to reinforced concrete, box culverts can support heavy vehicular or railway traffic overhead, making them perfect for highways, industrial zones, and rural infrastructure alike.

3. Customizable Dimensions

Concrete box culverts can be custom-made to suit specific hydraulic needs, road widths, and environmental conditions. Whether you need a culvert for a shallow stream or a major stormwater channel, sizing is never an issue.

4. Easy Installation

Precast concrete box culverts can be delivered ready to install, significantly reducing labor time and on-site disruptions. Compared to in-situ construction, precast solutions offer superior quality control and faster project completion.

Common Applications of Concrete Box Culverts

-

Road and highway drainage

-

Railway underpasses

-

Irrigation and agricultural canals

-

Urban stormwater management

-

Pedestrian or animal crossings

-

Bridge replacements in rural areas

Their versatility allows them to serve both functional and ecological purposes, helping engineers minimize environmental impact.

Precast vs. Cast-in-Place Box Culverts

Precast Concrete Box Culverts

-

Manufactured off-site

-

Faster installation

-

Consistent quality and strength

-

Ideal for projects with tight deadlines

Cast-in-Place Concrete Box Culverts

-

Built on-site with formwork

-

More flexible for unusual shapes or site constraints

-

Slower to construct but can adapt to complex design requirements

Both methods have their place, and the choice depends on budget, timeline, and project complexity.