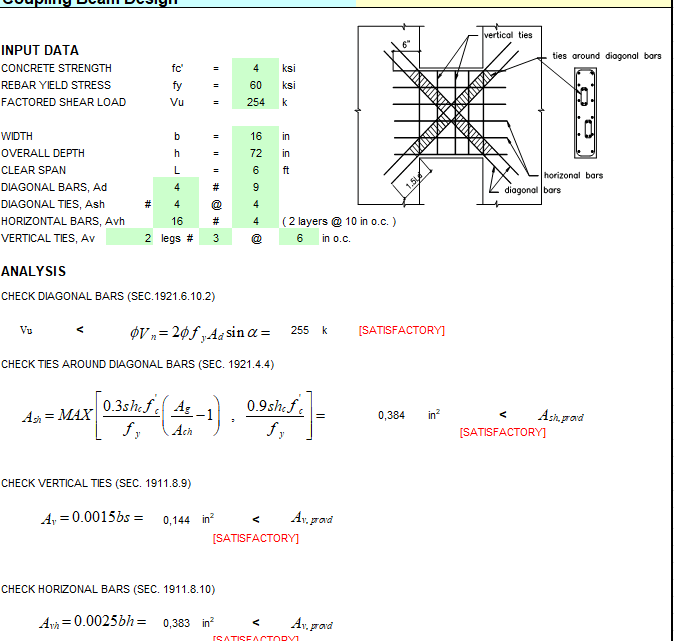

Coupling Beam Design Excel Sheet

12 July 2019Table of Contents

Coupling Beam Design Excel Sheet

Coupling beams are critical structural elements used in reinforced concrete buildings to enhance seismic resistance, stiffness, and load transfer between shear walls. While often overlooked in favor of more prominent components like columns or slabs, coupling beams play a vital role in the overall lateral performance of high-rise and earthquake-resistant buildings.

What Is a Coupling Beam?

A coupling beam is a short, often deep reinforced concrete beam that connects two adjacent vertical elements—typically shear walls—around openings like doors or windows. These beams are designed to transfer shear forces between walls, thereby coupling their behavior and improving the ductility and energy dissipation capacity of the structural system during seismic events.

Common Applications:

-

High-rise buildings

-

Earthquake-prone zones

-

Shear wall systems

-

Nuclear power plants and other critical structures

Key Functions of Coupling Beams

Understanding the purpose of coupling beams is essential for structural designers and engineers:

-

Energy Dissipation: Coupling beams help absorb and dissipate seismic energy, reducing the risk of catastrophic failure.

-

Lateral Load Sharing: They allow shear walls to act together, increasing lateral stiffness and reducing drift.

-

Load Redistribution: Coupling beams aid in redistributing loads caused by wind, earthquakes, or uneven settlement.

-

Improved Ductility: Properly detailed beams provide the necessary ductility to comply with seismic design standards (e.g., ACI 318, Eurocode 8).

Types of Coupling Beams

Depending on geometry, loading, and construction constraints, coupling beams can be classified into several types:

1. Conventional Reinforced Coupling Beams

-

Uses horizontal and diagonal rebar

-

Suitable for shorter spans and moderate seismic activity

-

Easier to construct but less ductile under high loads

2. Diagonally Reinforced Coupling Beams

-

Reinforced with diagonal bars crossing the beam diagonally

-

Provides higher ductility and strength

-

Recommended for high seismic zones

3. Post-Tensioned Coupling Beams

-

Uses tendons for pre-compression

-

Offers excellent crack control and reusability after a seismic event

4. Steel Coupling Beams

-

Made of steel or composite materials

-

Faster construction, ideal for modular buildings

Design Considerations

Designing a coupling beam involves several technical factors:

-

Aspect Ratio (L/d): Affects the structural behavior. Shorter, deeper beams are more effective in seismic zones.

-

Shear Strength: Should be sufficient to avoid brittle failure.

-

Reinforcement Detailing: Proper anchorage and confinement are critical.

-

Compatibility with Shear Walls: The interaction must be accurately modeled for correct force transfer.

Relevant Codes:

-

ACI 318: American Concrete Institute

-

Eurocode 8: European standard for earthquake-resistant design

-

IS 13920: Indian standard for ductile detailing of reinforced concrete structures

Common Mistakes in Coupling Beam Construction

-

Insufficient Reinforcement Detailing – May lead to premature failure under seismic loads.

-

Poor Concrete Compaction – Causes voids and weakens the beam.

-

Incorrect Placement of Diagonal Bars – Reduces the energy absorption capacity.

Future Trends in Coupling Beam Technology

With the evolution of performance-based design and advanced simulation tools, the engineering of coupling beams is entering a new era:

-

Fiber-reinforced concrete and engineered cementitious composites (ECC) are being explored for higher ductility.

-

Prefabricated coupling beam modules are being tested for faster construction in high-rise buildings.

-

Smart sensors embedded in beams for real-time health monitoring.

Coupling beams, though small in size compared to shear walls or columns, are indispensable in ensuring a building’s resilience, safety, and performance—especially in seismic zones. As urban landscapes grow taller and earthquake risks remain a pressing concern, the correct understanding and implementation of coupling beams can be the difference between structural success and failure.