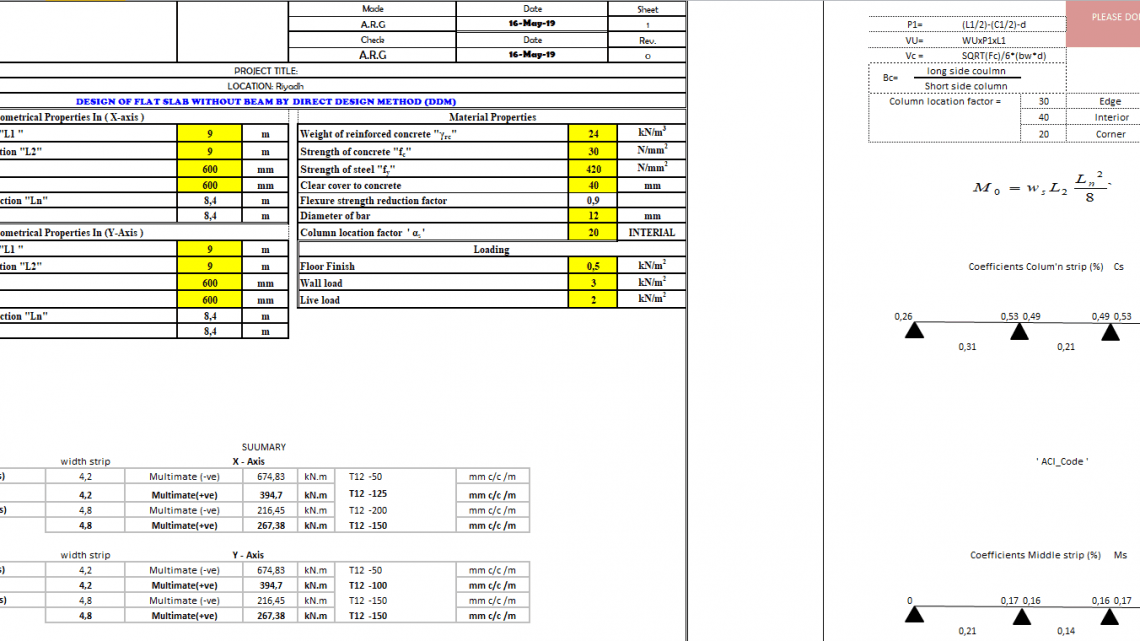

Design of Flat Slab Without Beam Spreadsheet

19 July 2025Table of Contents

Design of Flat Slab Without Beam Spreadsheet

What is a Flat Slab Without a Beam?

A flat slab is a reinforced concrete slab that rests directly on supporting columns, without the use of beams.[1] The load from the slab is transferred directly to the columns, creating a clean, unobstructed ceiling.[2] This is in contrast to conventional slab-beam systems where the slab is supported by beams, which then transfer the load to the columns.[2] Flat slabs must have a minimum thickness, as specified by building codes like IS 456:2000, which mandates at least 125 millimeters.[1]

There are a few variations of the flat slab system:

-

Simple Flat Slab: This is the most basic form, with a uniform thickness, resting directly on columns. It’s suitable for spans of roughly 6 to 9 meters.[1][3]

-

Flat Slab with Drop Panels: In this type, the slab is thickened around the columns. These “drop panels” increase the slab’s shear strength and its ability to resist negative bending moments.[3][4]

-

Flat Slab with Column Heads: Here, the tops of the columns are widened, creating “column capitals.” This also enhances the shear strength of the slab.[5]

The Advantages of Going Beam-Free

The increasing popularity of flat slab construction is no accident. It offers a multitude of benefits that appeal to architects, engineers, and building owners alike.

Architectural Freedom and Flexibility

One of the most significant advantages of flat slabs is the design flexibility they offer. The absence of beams creates a clean, flat soffit, allowing for open, spacious interiors.[6][7] This gives architects the freedom to place partition walls anywhere they choose, creating versatile and adaptable room layouts.[5][8] The uninterrupted ceiling also allows for better diffusion of natural light and improved air circulation.[9][10]

Faster and More Economical Construction

Eliminating beams simplifies the construction process significantly.[7] The formwork required is less complex, which speeds up construction time and reduces labor costs.[10][11] The use of large table formwork can further accelerate the building process.[8] Some studies have shown that the total cost of a flat slab structure can be 12-16% lower than a conventional slab building.[12]

Reduced Building Height and Foundation Load

Without deep beams, the overall height of each floor can be reduced.[8] This can lead to a significant reduction in the total height of a multi-story building, saving on the cost of vertical elements and reducing the load on the foundation.[5][8]

Simplified Service Installation

The flat ceiling surface makes the installation of mechanical and electrical services, such as air conditioning ducts, fire suppression systems, and electrical conduits, much easier and more efficient.[1][8] There’s no need to bend cables or cut through beams, which simplifies coordination between different trades.[13]

Critical Design Considerations: Punching Shear and Deflection

While the benefits are numerous, designing a flat slab without beams requires careful consideration of two critical factors: punching shear and deflection.

Punching Shear: The Achilles’ Heel

Punching shear is a potential failure mode where a column could effectively “punch” through the slab due to concentrated stress.[14][15] This is a major concern in flat slab design and has been the cause of structural collapses in the past.[15] The thickness of the slab, the size of the columns, and the amount and placement of reinforcement are all crucial in resisting punching shear.[15] To counteract this, engineers may use drop panels, column capitals, or special shear reinforcement.[10][16]

Controlling Deflection and Cracking

Flat slabs can be more prone to deflection and cracking than traditional slab-beam systems, especially under heavy loads.[17] The slab’s thickness is a key factor in controlling deflection.[16] Careful analysis and proper reinforcement detailing are essential to ensure the long-term serviceability of the slab.

Flat Slab vs. Conventional Slab: A Head-to-Head Comparison

| Feature | Flat Slab | Conventional Beam-Slab System |

| Load Transfer | Slab directly to columns[2] | Slab to beams, then to columns[2] |

| Architectural Flexibility | High, allows for open layouts[6] | Limited by beam placement |

| Construction Speed | Faster due to simpler formwork[7] | Slower and more complex |

| Cost | Often more economical[11][12] | Can be more expensive due to additional formwork and labor |

| Building Height | Reduced floor-to-floor height[8] | Increased floor height due to beam depth[2] |

| Service Installation | Easier and more direct[1] | More complex, requires coordination around beams |

| Key Design Challenge | Punching shear[14][15] | Bending moments in beams |

The Future of Construction is Flat

The flat slab without beams is more than just a design trend; it’s a testament to the ongoing innovation in structural engineering. By offering a combination of aesthetic freedom, construction efficiency, and potential cost savings, it’s a system that is well-suited for a wide range of applications, including high-rise buildings, commercial spaces, parking garages, and hotels.[4][10] While the design requires meticulous attention to detail, particularly regarding punching shear and deflection, the advantages it presents are undeniable. As architects and engineers continue to push the boundaries of design, the flat slab is set to become an even more prominent feature in the skylines of the future.