Design Of Circular Water Tank Spreadsheet

4 May 2025Table of Contents

Design Of Circular Water Tank Spreadsheet

Water storage is one of the most crucial aspects of civil infrastructure, and circular water tanks are widely used due to their cost-effectiveness and structural efficiency. Whether for residential, commercial, or agricultural use, designing a circular water tank requires careful consideration of hydraulic, structural, and material factors. In this article, we’ll break down the design process of a circular water tank, using straightforward language that civil engineers, students, and professionals can understand and apply.

Why Choose a Circular Water Tank?

Circular tanks are preferred for several reasons:

-

Uniform Stress Distribution: The circular shape allows internal water pressure to distribute evenly across the walls.

-

Material Efficiency: Compared to square or rectangular tanks, circular tanks use less surface area for the same volume, reducing construction material.

-

Ease of Construction: Reinforced concrete circular tanks are simpler to form and pour using rotating formwork systems.

-

Aesthetics and Durability: The shape naturally resists cracking due to uniform loading, improving longevity.

Key Design Considerations

1. Tank Capacity

The first step is to determine the required storage volume. This depends on:

-

Daily water demand

-

Emergency or fire reserve

-

Location (residential, industrial, rural, etc.)

Use the formula:

Volume (V) = π × R² × H

Where:

-

R = radius of the tank

-

H = height of water column

2. Material Selection

Most circular tanks are made from reinforced concrete (RCC), thanks to its durability and strength. However, for temporary or small-scale uses, polyethylene or steel tanks are also common.

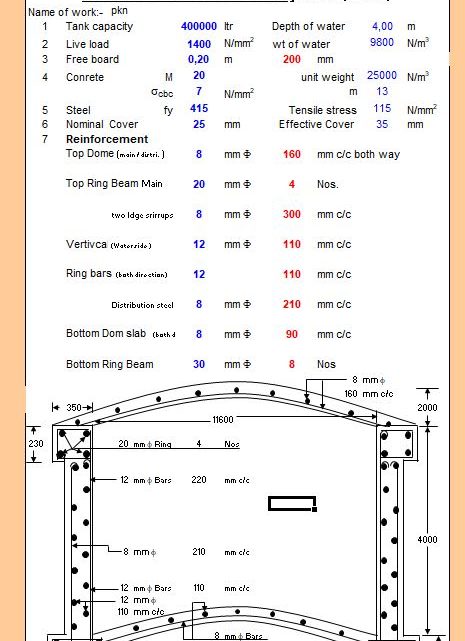

3. Wall Thickness and Reinforcement

Wall design is governed by hoop tension caused by the internal pressure of the water. The base of the tank walls experiences the highest pressure, requiring more reinforcement.

Use this formula for hoop tension (T):

T = (p × r) / t

Where:

-

p = pressure at the depth considered

-

r = radius

-

t = wall thickness

Add vertical reinforcement to resist bending moments, especially near the base.

4. Base Slab Design

The base slab supports the entire weight of water and tank structure. It is generally designed as a circular slab with a uniform thickness or a slightly domed shape to resist uplift pressure if groundwater exists.

5. Roof Design (if applicable)

Tanks storing potable water often require a cover to prevent contamination. Depending on the size, flat or domed RCC slabs are used. For larger tanks, steel trusses with sheeting may be used.

Sample Circular Tank Design

Let’s say we need a tank to store 100,000 liters (i.e., 100 m³) of water.

Assume a depth of water = 3.5 m

Using V = π × R² × H, rearranged as:

R² = V / (π × H)

=> R² = 100 / (3.14 × 3.5) ≈ 9.1

=> R ≈ 3.02 m

=> Diameter ≈ 6.04 m

This gives us a circular tank with an internal diameter of about 6 meters and a height of 3.5 meters. The wall thickness and reinforcement will depend on design loads, exposure conditions, and material grades. All must follow standards such as ACI 350 or IS 3370.

Common Design Codes to Follow

-

IS 3370 – Indian Standard for concrete water tanks

-

ACI 350 – Code requirements for environmental engineering concrete structures

-

BS EN 1992 (Eurocode 2) – Design of concrete structures

These codes provide detailed guidance on load combinations, crack control, durability, and safety factors.

Tips for Efficient Tank Design

-

Minimize dead space by optimizing dimensions.

-

Ensure proper waterproofing using admixtures or coatings.

-

Use construction joints and expansion joints as needed.

-

Allow for proper drainage and overflow provisions.

-

Consider seismic loads in high-risk areas.