Gravity Wood Beam Design Spreadsheet

3 May 2025Table of Contents

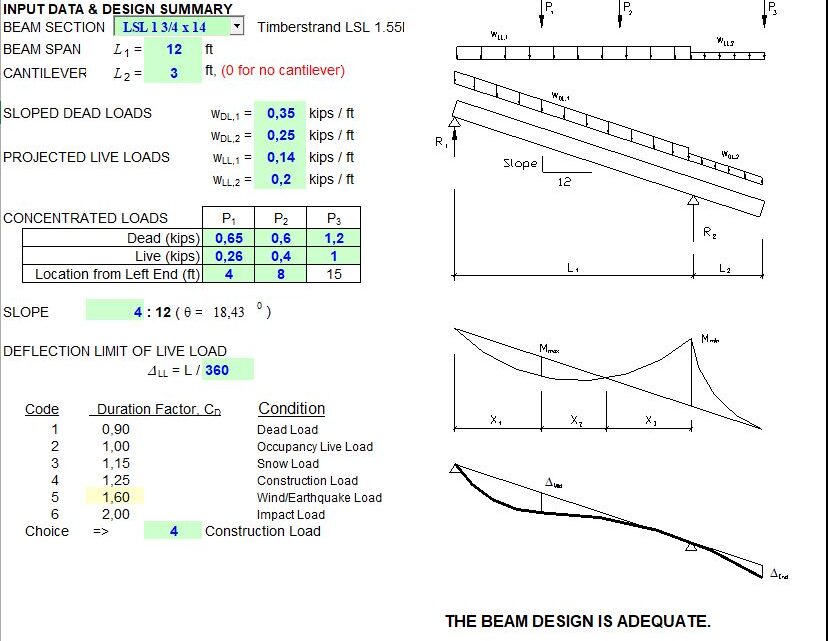

Gravity Wood Beam Design Spreadsheet

Wood has been a staple in structural design for centuries, and its appeal hasn’t waned. One of the most critical elements in wood construction is the beam—the unsung hero that quietly bears the weight of floors, roofs, and ceilings. This article dives deep into gravity wood beam design, offering expert insights for engineers, architects, contractors, and informed homeowners who want to understand how beams handle loads, ensure safety, and comply with modern building codes.

What Is Gravity Wood Beam Design?

Gravity wood beam design refers to the process of sizing and specifying wood beams to safely support loads that act due to gravity—namely, dead loads (permanent weights like flooring and roofing materials) and live loads (temporary weights like people, furniture, and snow).

When done right, this design ensures the beam won’t bend, sag, or fail under expected conditions. It’s a fundamental part of structural engineering and is used in everything from residential decks to massive commercial timber-framed buildings.

Key Elements of Gravity Load Design

To properly design a wood beam for gravity loads, several key factors must be considered:

1. Span Length

The longer the beam span, the stronger (and often deeper) it must be. Span length is the distance between two beam supports, such as posts or walls.

2. Load Calculations

Engineers must calculate:

-

Dead loads (e.g., weight of wood, insulation, drywall)

-

Live loads (e.g., foot traffic, furniture, snow, wind uplift—if applicable)

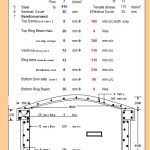

3. Material Properties

Different species of wood have different strengths. Douglas Fir, Southern Pine, and LVL (Laminated Veneer Lumber) are popular choices, each with specific bending and shear strengths.

4. Deflection Limits

Excessive deflection (sagging) can damage finishes or make a floor feel “bouncy.” Most codes limit deflection to L/360for floors (where L is the span in inches).

5. Beam Size and Type

Beams can be solid sawn lumber, engineered wood (like LVL or Glulam), or built-up (e.g., multiple planks nailed together). The choice affects both structural performance and cost.

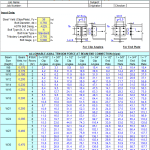

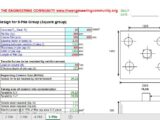

How to Size a Gravity Wood Beam

Here’s a simplified method often used in preliminary design. Always confirm with local codes and a licensed engineerbefore finalizing.

Step-by-step:

-

Determine total load per linear foot (PLF):

Add dead + live loads per square foot, then multiply by the tributary width the beam supports. -

Use span tables or design software:

Input load, span, and wood species to find the required beam size. -

Check bending, shear, and deflection:

Make sure the selected beam doesn’t exceed allowable stress limits. -

Add safety margins:

Follow building code requirements (typically include safety factors of 1.5+).