End Plate Moment Connection Spreadsheet

23 April 2019End Plate Moment Connection Spreadsheet

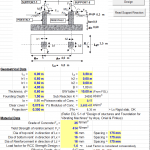

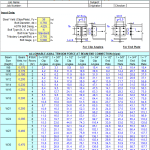

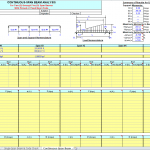

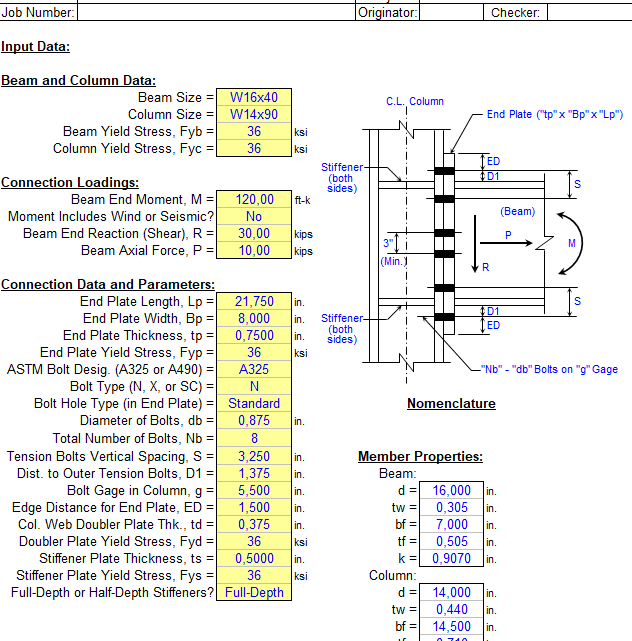

End Plate Moment Connection is a spreadsheet program written in MS-Excel for the purpose of analysis and design of end plate moment connections per the AISC 9th Edition (ASD) Manual. Specifically the program can analyze both single 4-tension bolt and 8-tension bolt configurations, as well as the conditions of having moment connections on each side of the column attached to the column flanges.

This program is a workbook consisting of five (5) worksheets, described as follows:

- Doc – Documentation sheet

- 4-Tension Bolt MC – Single 4-tension bolt end plate moment connection

- (2) 4-Tension Bolt MC’s – Double 4-tension bolt end plate moment connections

- 8-Tension Bolt MC – Single 8-tension bolt end plate moment connection

- (2) 8-Tension Bolt MC’s – Double 8-tension bolt end plate moment connections

All the worksheets are independent and self contained, so that you can move them from one workbook to another. All the worksheets are protected, but not with a password.

Program Assumptions and Limitations:

1. This program uses the database of member dimensions and section properties from the “AISC Shapes Database”, Version 3.0 (2001) as well as the AISC 9th Edition (ASD) Manual (1989).

2. This program is based on the non-seismic specific design procedures found in the following two references:

a. “Moment Connections – End Plate (Static Loading Only)” on pages 4-116 through 4-125 (Static Loading Only)” on pages 4-116 through 4-125, AISC 9th Edition (ASD) Manual (1989).

b. “Extended End-Plate Moment Connections” – AISC Steel Design Guide Series #4, by Thomas M. Murray, PhD, P.E., First Edition (AISC 1990).

c. “Stiffening of Wide-Flange Columns at Moment Connections: Wind and Seismic Applications” – AISC Steel Design Guide Series #13, by Charles J. Carter, P.E., Second Edition (AISC 2003).

3. The original theory used assumes that prying action is negligible and that the tension flange force is equally distributed among the tension bolts. End plates sized according to this AISC procedure herein should result in negligible prying forces at working stress. Thick end plates will result in reduced bolt prying action and are preferred to achieve desired connection rigidity. As a “rule-of-thumb”, for end plates with thicknesses greater than or equal to the bolt diameter, prying forces need not be checked.

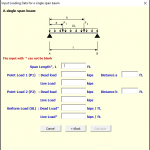

4. This program contains numerous “comment boxes” which contain a wide variety of information including explanations of input or output items, equations used, data tables, etc. (Note: presence of a “comment box” is denoted by a “red triangle” in the upper right-hand corner of a cell. Merely move the mouse pointer to the desired cell to view the contents of that particular “comment box”.)

Calculation Reference

AISC Steel Construction Manual