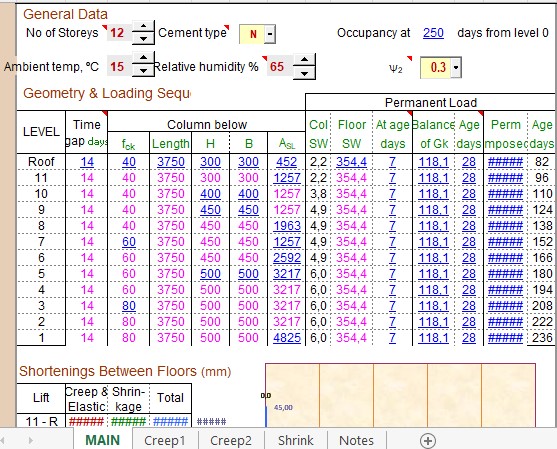

Axial Column Shortening Design and Calculation To EN 1992-1 2003 Spreadsheet

4 May 2025Table of Contents

Axial Column Shortening Design and Calculation Spreadsheet

Understanding Axial Column Shortening Design in High-Rise Structures

Axial column shortening is a critical aspect of structural engineering, especially in the design and construction of high-rise buildings. As structures grow taller, the differential shortening of columns due to axial loads becomes increasingly significant and must be carefully considered during the design phase to ensure safety, serviceability, and long-term performance.

In this article, we’ll explore what axial column shortening is, why it matters, and how engineers design for it in modern buildings.

What Is Axial Column Shortening?

Axial column shortening refers to the vertical displacement of columns under axial compressive loads. In simple terms, when a column carries a load, it compresses slightly. This compression can be due to:

-

Dead loads (self-weight of the structure)

-

Live loads (occupants, furniture)

-

Creep (long-term deformation under sustained load)

-

Shrinkage (mainly in concrete members)

-

Elastic deformation

While this shortening is often small, the variation of shortening between different columns — especially those carrying different loads or made from different materials — can cause differential settlement, leading to:

-

Cracked walls

-

Uneven floor levels

-

Misaligned mechanical and façade systems

Why Axial Shortening Design Matters in High-Rise Buildings

In tall buildings, the difference in column lengths and load intensities makes differential shortening a real design challenge. For example:

-

Core columns often carry higher loads and thus shorten more.

-

Perimeter columns, subjected to less gravity load, may not shorten as much.

-

The difference can cause stress in floor slabs and exterior walls if not properly managed.

This is where axial column shortening design plays a crucial role. It helps engineers predict, control, and accommodate differential movement before it leads to serviceability issues or expensive retrofits.

Factors Affecting Axial Shortening

Several key parameters influence the amount of shortening:

-

Material Type

Concrete columns experience creep and shrinkage, while steel columns primarily deform elastically. -

Load Intensity

Columns with higher axial loads will compress more. -

Column Geometry

Cross-sectional area and slenderness impact how much a column shortens. -

Time-dependent Effects

Long-term effects such as creep and shrinkage in concrete can significantly add to total shortening over time. -

Construction Sequence

The way a building is constructed — whether floor-by-floor or in segments — impacts load distribution and timing of shortening.

How Engineers Design for Column Shortening

Modern structural engineers use a variety of techniques to account for and control axial shortening, such as:

1. Differential Shortening Calculations

Designers perform detailed calculations to estimate the shortening in each column over time, factoring in material properties, loads, and time-dependent behavior.

2. Post-tensioned Floor Systems

These can be designed to accommodate differential movement and reduce cracking.

3. Construction Tolerances

Builders often leave adjustable gaps or inserts to absorb shortening-related movement.

4. Pre-cambering and Pre-setting

Engineers may pre-camber beams or pre-set columns to account for anticipated shortening during construction.

5. Use of Software Tools

Advanced structural analysis tools such as ETABS, SAP2000, or MIDAS include features for modeling axial shortening in tall buildings.

Best Practices for Controlling Axial Shortening

-

Perform early-stage shortening analysis during structural design

-

Use uniform materials and section sizes where possible to reduce differential effects

-

Coordinate closely with architects and MEP engineers to avoid clashes due to misalignment

-

Update shortening models as construction progresses

-

Monitor actual shortening using instrumentation on-site