Lime & Cement Stabilisation Process

8 December 2018Table of Contents

Lime & Cement Stabilisation Process

Introduction

Soil stabilisation, in terms of pavement construction, is the process of (usually insitu) pulverising and moisture conditioning by mixing various binders with soil, compaction and trimming as necessary. This improves soil characteristics preferred for construction in terms of moisture content, density, strength (CBR%), permeability, plasticity index and shrink swell characteristics. Most material types, clay through to crushed rock, are suitable for stabilisation. Seeking advice early during the design/feasibility stage enables planning for efficient use of stabilisation.

Stabilisation

Lime and/or cement stabilisation is often used to improve the properties of site won materials, to enable their use in a pavement and other like areas, such as dam foundations and building pad sites. Lime stabilisation of clay material reduces entrance cracking, whilst increasing the hardness of the material by up to ten times. The use of cement as a binder, after lime, can further increase the strength and durability towards that of concrete. Various binder blends, away from lime and cement, such as slag or fly ash, are commonly utilised for further benefit dependant on site conditions and requirements.

General Benefits of Soil Stabilisation

- Saturated, wet sites can be treated to provide a working platform within a day for project continuation during wet periods/seasons.

- Stabilisation recycles existing pavement by pulverising the existing pavement to 25mm down. Lime and or cement or other binders are then mixed with water as necessary. No imported materials and increased production rates means cost savings.

- Strength gains often over CBR 15% or 5 times the previous strength are the result of the realignment of particles and adjustment of moisture content allowing compaction at optimum moisture content.

- Reduce Plasticity Index (PI) in cohesive materials. For example a material with PI 20 will typically stabilise to PI < 10, say 8.

General Stabilisation for Lining Systems and Cohesive Expansion Material

- Reduce or eliminate the need for imported clay liner by stabilising insitu materials.

- Reduce permeability.

- Reduce Linear Shrinkage rate up to 10%.

- Environmental benefits of reduced geotextile, borrow pit clay and quarry import.

- Additional environmental benefits from reducing extra excavation and disposal by modification to suitable material.

- Improved structural stability through realignment of soil particles by ionic exchange between clay and lime.

- Increased Strength and durability.

- Reduced dispersion means reduced dispersion piping failure and increased erosion protection.

- Pulverisation to 40mm down of clay, extremely weathered limestone, mudstone and siltstone provides smaller diameter conglomerates and homogenous material throughout the stabilised layer eliminating lenses, streaks, rock fissures and faults providing reduced seepage.

Lime

Note that there are many variations of lime available but only quicklime is considered suitable for lime stabilisation in the pavement construction industry and general field construction activities. Quicklime is calcium oxide (CaO) supplied commercially in a dry powder form. Agriculture Lime is a calcium carbonate (CaC03) and not suitable for pavement construction. Hydrated Lime is calcium hydroxide (Ca(OH)2) often used in the laboratory for lime saturation testing, not generally used on site for pavement construction.

Hydrated lime (calcium hydroxide), is produced by reacting water with quicklime (calcium oxide). CaO + H2O => Ca(OH)2. When calculated using the atomic weights, this converts practically to 5t Quicklime + 3t Water => 7t Hydrated lime + 1t Water Evapouration.

The pozzolanic reaction between lime with water and the silica and alumina in clay results in an ionic exchange, which permanently realigns the clay particles forming friable conglomerates. The new alignment of the particles provides less ability for the clay to absorb water around the particles. This makes the clay more waterproof, less expansive and therefore reduces the plasticity and linear shrinkage. The PI is often more than ½ and the shrinkage is often 10% of what it was. Practically this results in improved permeability less shrinkage cracking providing less chance of piping failure and seepage.

In a lime saturated environment (typically 3% to 4% quicklime), the clay-alumina and clay-silica become available to react with the free calcium to form calcium aluminates or silicates. The pozzolanic reaction is illustrated by the following equations:

Ca2+ + OH- + Available Clay Aluminium Calcium Aluminate Hydrate (CAH)

Ca2+ + OH- + Available Clay Silica Calcium Silicate Hydrate (CSH)

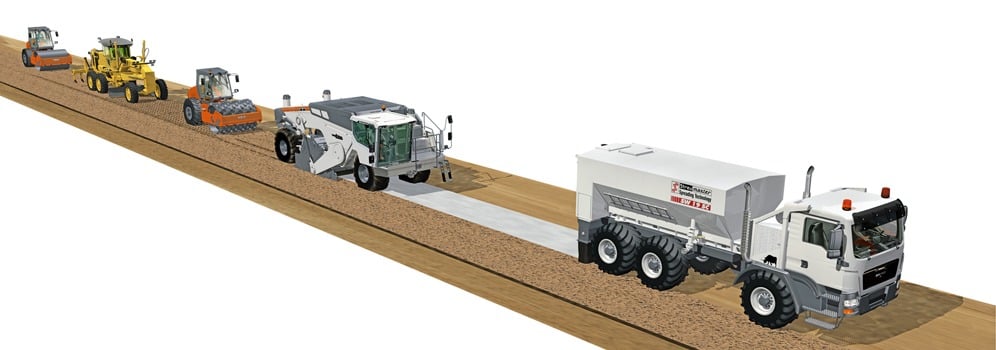

Stabilisation Process & Machinery

Insitu stabilisation procedures vary depending upon the type of project and the binder used. All machinery suitable for the process is purpose built for stabilisation. A range of purpose built equipment has been developed according to specific requirements of various site conditions and design specifications for the process to be effective. Adaptation of agricultural equipment and other equipment does not meet specification requirements and results in a process failure.

Preparation

Prior to stabilisation commencing it is important to ensure the surface is prepared for stabilisation ahead of stabilisation. Preparation of a surface for stabilisation includes pegging out for stringing as necessary, trimming to approximate levels and shaping to shed water and sufficient drainage to prevent water ponding where possible. Note that due to the addition of binders and density changes, some bulking may occur, however this may also be balanced by other factors such as reducing the moisture content or increasing the density of the underlying material during compaction. Immediately prior to stabilisation, the surface should be ripped to the required depth to identify and remove unsuitable material such as obstacles, organics and material too hard to stabilise.

Spreader

the Stabil-Lime Group operates a range of purpose built lime and cement spreader trucks including an articulated 4×4 all terrain spreader for particularly boggy sites. This enables the supply and distribution of a full range of binder products suitable for the insitu stabilisation process. Leading technologies are incorporated into all trucks to ensure accurate binder spread rates and containment of dust.

- On board computers linked to load cells and farm scan distance measuring devices assist in assuring accurate spread rates.

- All spreader trucks have sealed bulk bins to ensure the product does not start to react until it is on the ground ready to be mixed into the pavement. Spread rates (kg/m2) must vary in accordance with varying ground conditions.

- Additional mat test can be carried out in order to confirm and adjust the spreading rate.

Water Truck

Especially during the drier months, water must be added to ensure optimum moisture content is maintained for compaction. Depending on soil conditions and moisture content water can be added before and or after spreading any binder or directly into the mixing chamber by linking the water truck to the mixer where appropriate. Not only is water vital to ensure optimum moisture content at compaction, water initiates the necessary chemical reactions with most binders.

Stabilising Machine

Prior to stabilisation commencing it is important to ensure the surface is prepared for stabilisation ahead of stabilisation. Preparation of a surface for stabilisation includes pegging out for stringing as necessary, trimming to approximate levels and shaping to shed water and sufficient drainage to prevent water ponding where possible. Note that due to the addition of binders and density changes, some bulking may occur, however this may also be balanced by other factors such reducing the moisture content or increasing the density of the underlying material during compaction. Immediately prior to stabilisation, the surface should be ripped to the required depth to identify and remove unsuitable material such as obstacles, organics and material too hard to stabilise. Rotary hoe type attachments to bob cats, tractors and the like are not accepted by the Industry for pavement construction as they are not mixing chambers, they do not ensure homogenous mixing or accurate depth control amongst other faults. Research shows pavements mixed with such machines often fail within 1-3 years because the binder and moisture have not been mixed thoroughly.

Compaction

Compaction commences after mixing. Typically stabilised materials are compacted to 95% standard, however higher compaction standards are achievable. Insitu mixing up to 400mm in a single layer requires compaction equipment large enough to achieve density throughout a layer this thick. Typically large self propelled vibratory padfoot rollers are used initially for deep compaction followed by a similar smooth drum to complete compaction of the full layer.

Final Trimming

It is normal to commence trimming the pavement before the completion of the compaction operation, ensuring good bonding of any corrected shape before is finished.

Considerations for Stabilisation

By seeking our advice early during the development stages of a project we can ensure savings are maximised by optimising the use of stabilisation in designs to reduce double handling and import and export of materials. We employ a number of qualified engineers and project managers offering sound advice based on years of experience.

In order to assess a site accurately in terms of stabilisation, ideally the following information is considered:

- Geotechnical data including site conditions, material type and depth, sub-grade and existing pavement material.

- Construction conditions and loading.

- Geometric site layout proposed and existing.

- Proposed minimum area to be treated.

- Specification requirements typically in terms of density, CBR strength or binder content if provided.

- Proposed award and commencement dates.