Pile Foundation Tank Support Spreadsheet

24 January 2026Table of Contents

Pile Foundation Tank Support: Complete Guide to Design, Installation, and Best Practices

When it comes to supporting large storage tanks, pile foundation systems represent one of the most reliable and cost-effective solutions available. Whether you’re planning a water treatment facility, oil storage terminal, or industrial chemical plant, understanding pile foundation tank support is crucial for ensuring structural integrity and long-term performance.

What is Pile Foundation Tank Support?

Pile foundation tank support is a deep foundation system specifically designed to transfer the substantial loads of storage tanks to stable soil or rock layers beneath the surface. Unlike shallow foundations that rely on surface soil bearing capacity, pile foundations extend deep into the ground, providing superior load distribution and stability for heavy tank structures.

These specialized foundation systems are essential when surface soils lack adequate bearing capacity, when settlement control is critical, or when tanks must be constructed in challenging ground conditions such as soft clay, expansive soils, or areas with high water tables.

Why Choose Pile Foundations for Tank Support?

Superior Load-Bearing Capacity

Storage tanks, particularly those holding liquids, generate enormous vertical loads that can exceed thousands of tons. Pile foundations excel at transferring these loads to competent soil strata or bedrock, ensuring the tank remains stable throughout its operational life.

Minimal Settlement Control

One of the primary advantages of pile foundation tank support is exceptional settlement control. Differential settlement can cause catastrophic tank failure, including shell distortion, welding seam rupture, and product leakage. Piles minimize both total and differential settlement by engaging stronger soil layers deep underground.

Versatility Across Soil Conditions

Pile foundations perform reliably across diverse geological conditions where conventional spread footings would fail. From coastal areas with saturated soils to regions with expansive clays, pile systems adapt to challenging environments that would otherwise require extensive soil improvement.

Resistance to Lateral Forces

Beyond vertical load support, pile foundations provide excellent resistance to lateral forces from wind, seismic activity, and hydrostatic pressures. This multi-directional stability is particularly valuable for tall tanks with high centers of gravity.

Types of Pile Foundations for Tank Support

Driven Piles

Driven piles are pre-manufactured elements hammered into the ground using specialized equipment. Common materials include concrete, steel, and timber, with concrete and steel being preferred for tank applications.

Advantages: High load capacity, proven performance, quality control during manufacturing, suitable for various soil conditions.

Considerations: Installation vibrations may affect nearby structures, potential for pile damage during driving, noise concerns in urban areas.

Bored Piles (Drilled Shafts)

Bored piles are cast-in-place concrete elements created by drilling a hole and filling it with reinforced concrete. These are particularly popular for large diameter tank supports.

Advantages: Minimal vibration during installation, larger diameter options available, excellent for difficult soil conditions, can be socketed into rock.

Considerations: Construction quality depends heavily on execution, groundwater management required, typically more expensive than driven piles.

Micro Piles

Micro piles are small-diameter drilled piles, typically less than 300mm in diameter, installed in groups to support tank loads.

Advantages: Low headroom installation possible, minimal disturbance, excellent for retrofitting existing tanks, versatile in restricted spaces.

Considerations: Requires numerous piles for high loads, specialized installation equipment, higher cost per ton of capacity.

Helical Piles (Screw Piles)

Helical piles feature steel shafts with helical bearing plates, screwed into the ground like giant screws.

Advantages: Immediate load capacity, installation monitoring available, low vibration, suitable for small to medium tanks.

Considerations: Limited to certain soil types, capacity constraints compared to larger pile types, corrosion protection essential.

Design Considerations for Pile Foundation Tank Support

Load Analysis

Accurate load determination forms the foundation of successful pile design. Engineers must account for:

- Dead loads: Tank shell weight, foundation weight, permanent equipment

- Live loads: Product weight at maximum fill, operating equipment, personnel

- Environmental loads: Wind forces, seismic loads, snow accumulation

- Hydrostatic pressures: Internal and external water pressures

- Thermal effects: Expansion and contraction from temperature variations

Geotechnical Investigation

Comprehensive soil investigation is non-negotiable for pile foundation design. This includes:

- Soil boring and sampling to characterize subsurface conditions

- Standard Penetration Tests (SPT) for soil strength evaluation

- Cone Penetration Tests (CPT) for continuous soil profiling

- Laboratory testing to determine soil properties

- Groundwater level assessment and seasonal variation analysis

Pile Capacity Determination

Engineers calculate pile capacity using both static analysis methods and dynamic load testing. Factors considered include:

- Skin friction along the pile shaft

- End bearing resistance at the pile tip

- Soil properties along the pile length

- Pile material and geometry

- Installation method effects on soil properties

Settlement Analysis

Even with pile foundations, settlement prediction remains critical. Calculations address:

- Elastic compression of the pile itself

- Settlement of pile groups versus individual piles

- Consolidation of soil layers beneath pile tips

- Time-dependent settlement behavior

Pile Group Effects

Tanks typically require multiple piles working together. Group effects include:

- Overlapping stress zones reducing efficiency

- Block failure potential for closely spaced piles

- Increased settlement compared to isolated piles

- Load distribution variations among group members

Pile Cap Design for Tank Foundations

The pile cap serves as the interface between the tank structure and the pile foundation system. Proper pile cap design ensures effective load transfer and structural integrity.

Ring Beam Configuration

Most cylindrical tanks utilize ring beam pile caps that distribute loads around the tank perimeter. This configuration offers:

- Efficient load distribution to perimeter piles

- Reduced material quantities compared to solid slabs

- Accommodation of tank shell tolerances

- Simplified construction sequencing

Mat Foundation with Piles

For larger tanks or those requiring uniform support, a complete reinforced concrete mat supported by piles provides:

- Uniform support across the entire tank bottom

- Enhanced resistance to differential settlement

- Simplified tank bottom construction

- Additional storage of leaked product (secondary containment consideration)

Pile Cap Reinforcement

Proper reinforcement design addresses:

- Punching shear around individual piles

- Flexural stresses from load transfer

- Crack control for durability

- Connection details to tank structure

Installation Best Practices

Pre-Installation Planning

Successful pile installation begins with thorough planning:

- Establish clear site access routes for equipment

- Identify and protect underground utilities

- Set up quality control procedures and testing protocols

- Develop contingency plans for unexpected conditions

- Coordinate with tank fabrication and erection schedules

Installation Monitoring

Real-time monitoring during installation provides quality assurance:

- Track pile driving resistance or drilling parameters

- Monitor pile verticality and alignment

- Record installation depths and refusal criteria

- Document any anomalies or changed conditions

- Perform integrity testing on selected piles

Quality Control Measures

Rigorous quality control ensures foundation performance:

- Pile load testing (static or dynamic) on representative samples

- Non-destructive integrity testing using sonic or ultrasonic methods

- Concrete quality verification through cylinder testing

- Reinforcement placement inspection before concrete placement

- Documentation of all deviations from design specifications

Common Challenges and Solutions

Obstructions and Boulders

Underground obstructions can halt pile installation. Solutions include:

- Pre-drilling through obstructions before pile driving

- Using robust pile sections capable of penetrating obstacles

- Adjusting pile locations within acceptable tolerance limits

- Employing alternative pile types better suited to obstruction penetration

Groundwater Management

High groundwater creates installation challenges:

- Dewatering systems to lower water table temporarily

- Tremie concrete placement methods for submerged piles

- Bentonite slurry support for drilled pile excavations

- Permanent drainage systems for ongoing water control

Pile Heave and Relaxation

Soil displacement during pile driving can cause previously installed piles to heave:

- Strategic installation sequencing from center outward

- Re-driving affected piles after adjacent installation

- Adequate time allowance for soil stress relaxation

- Pre-drilling in highly displacement-sensitive soils

Corrosion Protection

Long-term durability requires corrosion protection strategies:

- Concrete cover thickness specification for reinforcement protection

- Epoxy-coated reinforcement in aggressive environments

- Cathodic protection systems for steel piles

- Protective coatings appropriate to exposure conditions

Maintenance and Inspection

Even well-designed pile foundations require periodic evaluation:

Regular Monitoring

Establish baseline measurements and monitor:

- Tank settlement through precision surveying

- Differential movement between measurement points

- Groundwater level fluctuations

- Signs of foundation distress (cracks, spalling)

Inspection Protocols

Implement systematic inspection programs:

- Visual inspection of exposed foundation elements

- Non-destructive testing of accessible pile portions

- Evaluation of pile cap condition and reinforcement exposure

- Assessment of drainage system functionality

Rehabilitation Options

When issues are identified, intervention options include:

- Additional pile installation to supplement capacity

- Grouting to improve load transfer or soil properties

- Underpinning existing foundations with new elements

- Load reduction through operational modifications

Cost Considerations

Understanding cost factors helps optimize foundation selection:

Initial Capital Costs

Primary cost drivers include:

- Pile quantity, type, and length

- Mobilization of specialized installation equipment

- Geotechnical investigation depth and extent

- Pile cap size, reinforcement density, and concrete quality

- Testing and quality assurance programs

Life-Cycle Economics

Long-term value assessment considers:

- Maintenance requirements and frequency

- Expected service life and durability

- Operational flexibility and expansion capability

- Risk mitigation value (avoiding catastrophic failure costs)

Value Engineering Opportunities

Cost optimization strategies include:

- Alternative pile type evaluation for site-specific conditions

- Pile spacing and configuration optimization

- Construction methodology selection

- Specification refinement based on actual soil conditions

Regulatory and Code Requirements

Tank foundation design must comply with applicable standards:

International Standards

Key references include:

- API 650 (Welded Tanks for Oil Storage) – foundation requirements

- ACI 318 (Building Code Requirements for Structural Concrete)

- International Building Code (IBC) – foundation provisions

- Eurocode 7 (Geotechnical Design) – pile foundation guidance

Local Building Codes

Always verify requirements with local authorities:

- Permit requirements for foundation construction

- Special inspection mandates

- Seismic design provisions

- Environmental protection regulations

Conclusion

Pile foundation tank support represents a sophisticated engineering solution that ensures safe, reliable storage tank operation across challenging site conditions. From initial geotechnical investigation through design, installation, and long-term monitoring, success requires expertise at every phase.

Whether you’re planning a new tank installation or evaluating an existing facility, understanding pile foundation principles empowers informed decision-making. The investment in proper foundation engineering pays dividends through decades of trouble-free operation, avoided failures, and regulatory compliance.

For complex or critical tank projects, engaging experienced foundation engineers and contractors specializing in pile installation ensures your facility meets performance expectations while optimizing construction costs and schedules. The foundation literally supports everything above it—making it the most critical element deserving thorough attention and expert execution.

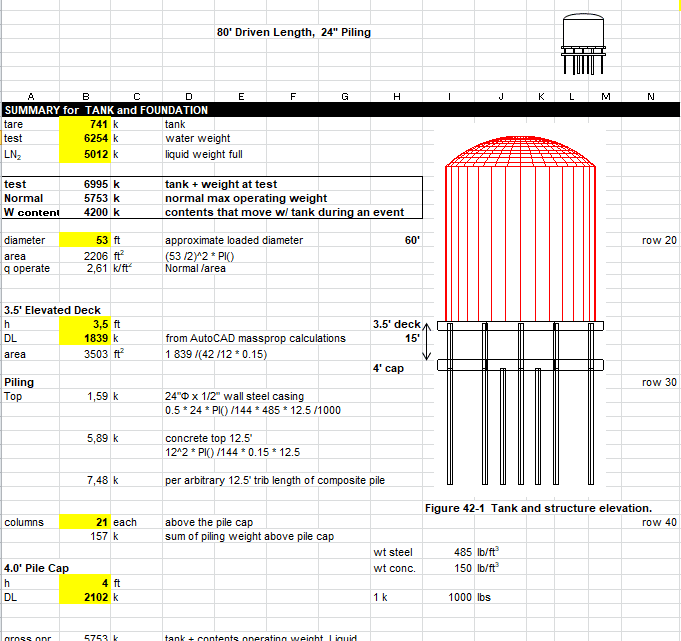

Free Pile Foundation Design Spreadsheet Tool

To help engineers and designers with pile foundation calculations for tank support projects, we’re offering a comprehensive Excel-based design spreadsheet as a free download.

What’s Included in the Spreadsheet

This practical calculation tool (file: 42 Pile Foundation.xls) provides automated calculations and design aids for pile foundation analysis, helping streamline your preliminary design process and verify capacity calculations.

Benefits of Using This Tool

- Time-saving calculations: Automate repetitive computational tasks

- Quick feasibility studies: Evaluate different pile configurations rapidly

- Design verification: Cross-check manual calculations or software outputs

- Educational resource: Understand pile foundation design principles through worked examples

- Preliminary sizing: Develop initial estimates for project planning and budgeting

How to Use the Spreadsheet Effectively

While this spreadsheet serves as a valuable design aid, always remember that:

- Final designs should be reviewed and sealed by licensed professional engineers

- Site-specific conditions may require adjustments beyond spreadsheet capabilities

- Local building codes and standards must be verified and applied

- Geotechnical recommendations from qualified soil engineers should govern design parameters

- The tool complements, but does not replace, engineering judgment and experience

Download the Pile Foundation Design Spreadsheet Here

This resource is provided for educational and preliminary design purposes. We recommend using it alongside professional engineering consultation for critical tank foundation projects.