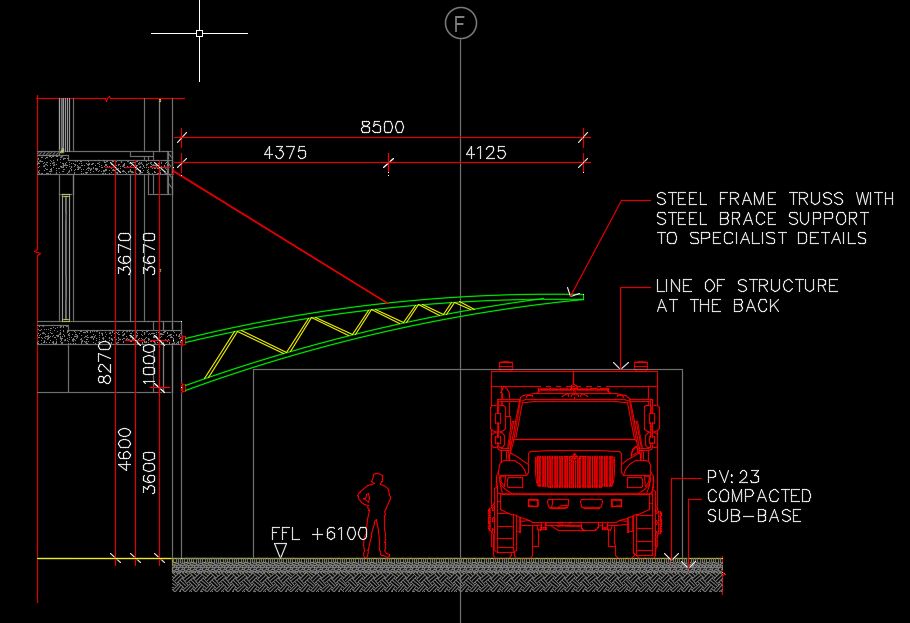

Steel Brace Support Autocad Free Drawing

4 May 2025Table of Contents

Steel Brace Support Autocad Free Drawing

When it comes to modern structural engineering, steel brace support plays a vital role in ensuring the safety, stability, and performance of buildings and infrastructure. These essential components are designed to resist lateral forces such as wind and earthquakes, keeping structures standing strong even under extreme conditions.

What is Steel Brace Support?

Steel brace support refers to steel components strategically installed in a structural frame to provide lateral support. Unlike vertical or horizontal members that mainly bear gravity loads, bracing systems control horizontal movement and prevent swaying or collapse due to lateral loads. They act like the skeleton’s ligaments—providing strength, flexibility, and resilience.

Types of Steel Bracing Systems

Steel bracing comes in various configurations, each suited to specific applications. The most common types include:

1. Diagonal Bracing

This is the simplest form, where steel members connect diagonally between columns and beams. It can be:

-

Single diagonal

-

Cross (X) bracing

-

K-bracing

2. Chevron or V-Bracing

Two diagonal braces meet at a central point on a horizontal beam, forming a ‘V’ shape. It’s commonly used in architectural applications for its clean look.

3. Inverted V-Bracing

Similar to Chevron, but the point of the V is inverted, distributing loads differently and often used to accommodate architectural needs or mechanical systems.

4. Eccentric Bracing

This design includes intentional offsets between braces and beams to allow limited movement and energy dissipation during earthquakes, making it popular in seismic zones.

Key Benefits of Steel Brace Support

Using steel braces in construction offers multiple advantages:

Improved Lateral Stability

Steel bracing strengthens the frame and limits horizontal displacement, ensuring safety in high-wind and seismic areas.

Cost-Effective Reinforcement

Compared to thicker columns or walls, adding steel braces is a cost-efficient way to enhance structural strength without increasing the building’s footprint.

Flexible Design

Steel braces are versatile and can be integrated into both new constructions and retrofits, accommodating a wide variety of architectural and functional needs.

High Strength-to-Weight Ratio

Steel offers excellent strength while being relatively lightweight, making it easier to install without compromising performance.

Durability

With proper corrosion protection, steel braces can last decades with minimal maintenance, even in harsh environmental conditions.

Applications of Steel Brace Support

Steel brace systems are used across a wide range of structures, including:

-

High-rise buildings

-

Industrial facilities

-

Warehouses

-

Bridges

-

Retrofit projects for older buildings

-

Schools and hospitals in seismic zones

Design Considerations

When designing a bracing system, structural engineers evaluate several factors:

-

Type and magnitude of lateral loads

-

Architectural constraints

-

Load path continuity

-

Member sizes and connections

-

Building codes and seismic requirements

To download more free Autocad templates you can visit www.cadtemplates.org