Steel Bridges Connecting Methods

29 January 2020Table of Contents

Steel Bridges Connecting Methods

Steel bridges, as well as other steel structures, are built of steel memberssuch as beams, columns, and truss members by connections or joints. Theuse of connections can affect the fabrication method, serviceability, safety,and the cost, thus they are particularly important in the steel bridge construction.

In general, the connection design should follow the principle thatshould be safe, reliable, simply in design and fabrication, easy installation, and should be able to save the materials and costs.

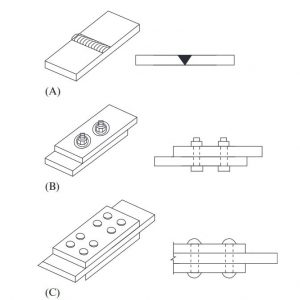

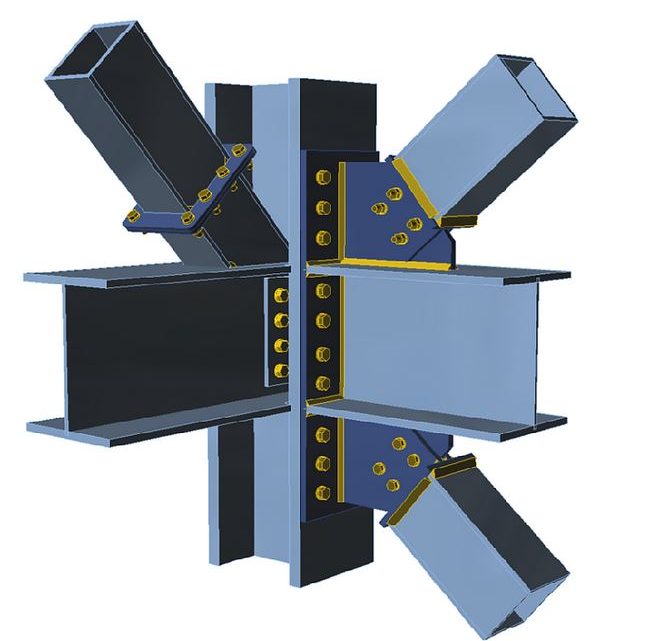

In steel bridges, the often used connecting methods include rivet connection, bolt connections, and welding connections, as shown in Fig.1.

Bolt connection is used earliest since the mid-18th century and stillis being used as one of the most important connections.

The rivet connection has been used since the early 19th century; there after the welding connection was also created and used in the end of 19th century.

The welding joint became very popular and gradually replaced the rivet connection in thesteel bridge construction. With the development of high-strength bolted connection at the mid-20th century, they are also widely used in the steel bridge construction.

Fig.1 Different connecting methods. (A) Welded connection. (B) Bolted connection.(C) Riveted connection

1. Bolted Connection

Bolted connection is more frequently used than other connection methods.They are very easy to operate and no special equipment is required. This is in particular due to the development of higher strength bolts, the easy to use and strong structural steel connections become possible.

In the bolt design, two kinds of forces including tension and shear forces should be considered.Bolted connection can be divided into ordinary bolted connection or high-strength bolted connection. Both of them are easy in installation, particularlysuitable for connection in the construction site.

Ordinary bolts are easy todisassemble and are generally used in temporary connections or those needto be disassembled. High-strength bolts are easy to disassemble, and theyhave higher strength and stiffness. However, the bolted connections alsohave some disadvantages because it is necessary to drill holes and adjustthe holes during the installation.

The cutting of the holes may weakenthe steel members and increase the use steel materials due to the memberoverlapping, and also this will increase the workload in the construction.There are many reasons that may result in the failure of the bolted connec-tions, such as overloading, over torquing, or damage due to corrosion.

2. Rivet Connection

From the mechanical behavior and design points of view, the rivet connectionis very similar to ordinary bolt connection. A rivet is a permanent mechanicalfastener, which was very popular for the early steel bridges due to their good performance in plasticity, toughness, integrity under statistic load, and fatigue performance under dynamic load.

Also, quality inspection of welded connection is also relatively easy than other connection methods.However, the rivet connection is rarely used in nowadays due to disad-vantages like complex in structure, high consumption of steel, high noiseduring the construction, etc., and gradually replaced by the bolted connec-tion and welded connection.

3. Welded Connection

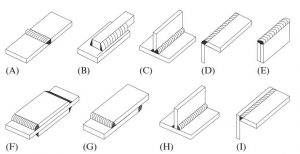

Welding is another connecting method used to connect steel components inthe fabrication factory and on bridge construction site. Common types ofwelds are butt welds, fillet welds, and plug welds, as shown in Fig.2.

The work place (in a factory or on site) is an important criterion fordeciding whether to choose a bolted or a welded connection. If the connec-tion is performed in a factory, it is generally most economically achievedthrough welding. Although it is technically possible for site welding, theadditional cost for setting up welding and testing facilities as well as theincreased erection time usually makes bolted connections become moreefficient.

Fig.2 Welded connections. (A) Butt joint. (B) Longitudinal joint. (C) Butt joint.(D) Corner joint-1. (E) Edge joint. (F) Transverse fillet joint. (G) Transverse fillet joint.(H) Tee joint. (I) Corner joint-2.