Tank Footing Design Based On ACI 318-14 Spreadsheet

14 February 2026Table of Contents

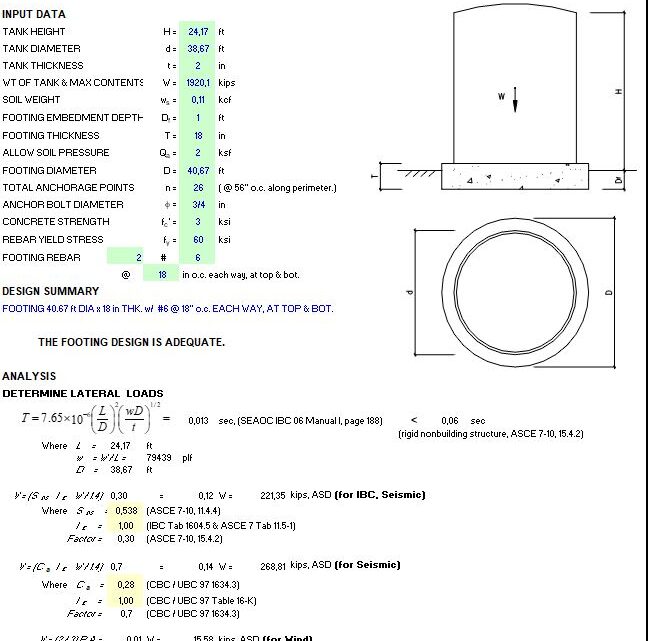

Tank Footing Design Based On ACI 318-14 Spreadsheet

Tank footing design is a critical aspect of structural and geotechnical engineering, especially for water tanks, oil storage tanks, and industrial liquid containment structures. Proper foundation design ensures structural stability, prevents excessive settlement, and resists cracking due to heavy loads.

This article provides a complete guide to tank footing design based on ACI 318-14, including design philosophy, load combinations, soil pressure checks, reinforcement requirements, and shear verification procedures.

Overview of ACI 318-14 for Foundation Design

ACI 318-14 (Building Code Requirements for Structural Concrete) provides structural design requirements for reinforced concrete elements, including foundations and footings.

Although geotechnical capacity is governed by soil reports, ACI 318-14 governs:

-

Strength design (LRFD method)

-

Load combinations

-

Flexural design

-

Shear design (one-way and two-way punching shear)

-

Minimum reinforcement requirements

-

Crack control provisions

Tank footings must satisfy both structural and geotechnical criteria.

Types of Tank Foundations

Depending on tank size and loading conditions, common foundation systems include:

1. Circular Mat (Raft) Foundation

Most common for large storage tanks. Provides uniform pressure distribution.

2. Ring Wall Foundation

Used for steel storage tanks where loads are transferred primarily at the tank shell.

3. Combined Footing

Used when tanks are adjacent to other structures.

Design Loads for Tank Footing (ACI 318-14)

Proper load evaluation is the first step in footing design.

1. Dead Load (D)

-

Self-weight of tank shell

-

Weight of concrete foundation

-

Weight of roof (if applicable)

2. Fluid Load (F)

Hydrostatic pressure from stored liquid.

3. Live Load (L)

Maintenance loads.

4. Wind Load (W)

Critical for empty tanks.

5. Seismic Load (E)

Important in seismic zones.

Load Combinations (ACI 318-14 Strength Design)

Typical strength design combinations include:

-

1.4D

-

1.2D + 1.6L

-

1.2D + 1.0E + 0.5L

-

1.2D + 1.0W + 0.5L

These combinations ensure safety under worst-case conditions.

Soil Bearing Pressure Check

Before structural design:

q=PA

Where:

-

q = soil pressure

-

P = total service load

-

A = footing area

Ensure:

q≤q allowable

Allowable soil bearing capacity is obtained from the geotechnical report.

Crack Control Considerations

Since tanks may contain liquids, crack control is important to prevent leakage.

ACI recommends:

-

Proper bar spacing

-

Adequate cover

-

Use of smaller diameter bars at closer spacing

Settlement and Stability Checks

Beyond ACI structural checks, engineers must verify:

-

Total settlement

-

Differential settlement

-

Sliding resistance

-

Overturning stability (for wind/seismic loads)

These are coordinated with geotechnical design.

Practical Design Tips

-

Use circular analysis models for accuracy

-

Increase thickness near tank wall if punching governs

-

Provide adequate concrete cover (minimum 75 mm for foundations)

-

Consider corrosion protection for aggressive environments

-

Use finite element software for large tanks

Common Mistakes in Tank Footing Design

-

Ignoring uplift forces in empty tank condition

-

Underestimating seismic loads

-

Neglecting punching shear

-

Not coordinating with geotechnical engineer

-

Insufficient crack control reinforcement

Conclusion

Tank footing design based on ACI 318-14 requires careful evaluation of structural loads, soil conditions, flexural capacity, and shear strength. Both one-way and two-way shear checks are critical, especially for large-diameter storage tanks.

By following ACI 318-14 provisions and coordinating with geotechnical reports, engineers can design safe, durable, and cost-effective tank foundations.

Proper reinforcement detailing, load combinations, and stability checks ensure long-term performance under operational and environmental conditions.