THE MAIN TYPES OF SCAFFOLDING IN BUILDING CONSTRUCTION

11 May 2019Table of Contents

THE MAIN TYPES OF SCAFFOLDING IN BUILDING CONSTRUCTION

SCAFFOLDING

Scaffolding is a temporary rigid structure made of still, bamboo or timber. The primary aim of constructing a scaffold is to create a platform on which mason can work at different heights. Scaffolds also help to lift materials for the immediate uses at different heights

USEFUL TERMS RELATED TO SCAFFOLDING:

1. Standard: It is a vertical member supported on the ground.

2. Ledgers: Ledgers are the longitudinal horizontal members connected with standards.

3. Braces: Braces are the diagonal members that are connected with standards to stiffen the structure.

4. Put Logs: Put logs are the transverse horizontal members that are 90 cm in length and are generally spaced 120 cm apart. They are provided to support the working platform.

5. Transoms: When both the ends of put logs are connected with ledgers, it is called transoms.

6. Boarding: Boarding is a horizontal member supported by put logs. It is used to enable the mason and materials.

7. Guard Rail: It is similar to ledgers, used for a better protection at the working level.

8. Toe Board: It is a long horizontal board of wood used at the different working level.

TYPES OF SCAFFOLDING:

Different types of scaffolding are described below:

1. Brick layer’s scaffolding,

2. Mason’s scaffolding,

3. Steel or tubular scaffolding,

4. Needle scaffolding.

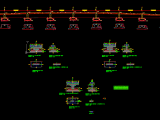

1. BRICK LAYER’S SCAFFOLDING:

This type of scaffolding consists of standards firmly secured in the grounds at 2.4 to 3 m. The standards are connected to each other by ledgers at every rise of 120 to 150 cm. They are provided on the building side of the standards and are secured in position by rope-lashing. Putlogs are lashed on the ledgers at one end and into the holes in the wall at the other end. In high scaffolding, cross braces are invariably used to stiffen the temporary structure. Braces consist of poles tied by rope-lashing on the standards.

2. MASON’S SCAFFOLDING:

Since it is difficult to leave holes in the stone masonry to provide a bearing for the putlogs, in mason’s scaffolding two frames of standards, at a distance of 1.5 m from the first one. Thus the mason’s scaffolding is entirely independent of the stone wall.

Close mason’s scaffolding: They are supposed to carry loads of heavy blocks of stones and the stresses produced on account of the lifting device and hence they are made stronger by placing the standards at a fairly close distance apart.

3. STEEL OR TUBULAR SCAFFOLDING:

The method of construction of steel scaffolding is similar to that of brick layer’s and mason’s scaffolding. The primary differences are

- Instead of using timber, steel tube of diameter of 40 m to 60 mm are used

- Instead of using rope lashing, special types of steel couples are used for fastening

- Instead of fixing the standards into the ground, it is placed on base plate

The gap between two standards in a row is generally kept within 2.5 m to 3 m. These standards are fixed on a square or round steel plate (known as Base Plate) by means of welding.

Ledgers are spaced at every rise of 1.8 m. Length of the putlogs are normally 1.2 m to 1.8m.

Advantages of the Steel Scaffolds are as follow:

- It can be erected or dismantled more rapidly in comparison to timber scaffolding. This helps in saving construction time.

- It is more durable than timber. Therefore it is economical in long run.

- It has more fire resisting capacity

- It is more suitable and safe to work at any height.

4. NEEDLE SCAFFOLDING:

When scaffolding is to provide for a building on the side of a busy street where the construction of ordinary scaffolding will obstruct the traffic on road, needle scaffold is used. The scaffold is erected from window corners of string courses by means of projecting needles. A needle is a timber beam which cantilevers out through the holes cut in the wall. From inside the needles are supported on sole pieces and are prevented from lifting up by vertical struts wedged between the needles and the headpieces. The projected end of the needle is supported by an inclined strut which rests on the window sill. The joint between the raking or inclined strut and the needle is clamped by mean of dogs. The arrangement provides the staging for the erection of ordinary type of scaffolding.