What are Floating Caissons? Advantages and Applications

27 May 2024Table of Contents

What are Floating Caissons? Advantages and Applications

Floating caissons play a crucial role in modern marine construction, offering durable and efficient solutions for building underwater foundations. Engineers use these robust structures extensively in projects like docks, piers, bridges, and offshore platforms. In this article, we explore the types, advantages, applications, and construction methods of floating caissons.

What Are Floating Caissons?

Also known as floating cofferdams, floating caissons are large, hollow structures made from reinforced concrete or steel. Engineers construct them offsite, float them to the project location, and sink them by filling them with water or ballast. Once positioned, they create a dry working environment ideal for building foundations and substructures.

Types of Floating Caissons

-

Open Caissons

These box-like structures remain open at the top and bottom. Crews float them to the site and continue excavation through the open bottom until they reach the desired depth. -

Box Caissons

Featuring a closed bottom and open top, box caissons are floated into position, filled with ballast, and then filled with concrete to form a solid foundation. -

Pneumatic Caissons

Engineers use compressed air in these caissons to keep water out of an airtight working chamber, enabling dry excavation even below the water table.

Advantages of Using Floating Caissons

-

Versatility

Floating caissons adapt to various marine construction needs, from small dock foundations to massive offshore platforms. -

Ease of Installation

Teams prefabricate caissons in controlled environments and transport them to the site for quick, efficient installation, reducing construction time and site disruption. -

Cost-Effectiveness

These structures eliminate the need for complex underwater excavation and temporary cofferdams, helping reduce project costs. -

Durability

Caissons built from steel or reinforced concrete resist harsh marine conditions and offer long-lasting performance. -

Lower Environmental Impact

Engineers install floating caissons with minimal disturbance to the seabed, protecting marine ecosystems compared to traditional methods.

Key Applications of Floating Caissons

-

Bridge Foundations

Builders use caissons to support bridge piers in deep water, providing a stable and dry environment for foundation work. -

Harbors and Docks

Caissons deliver the strength needed for dock and wharf foundations, supporting heavy loads and resisting tidal forces. -

Offshore Platforms

The oil and gas industry relies on caissons for platform foundations, where stability and safety are non-negotiable. -

Seawalls and Breakwaters

Coastal engineers use floating caissons to build seawalls and breakwaters that protect against erosion and storm damage.

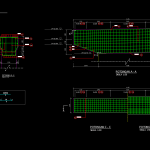

Construction Process of Floating Caissons

-

Design and Prefabrication

Engineers design caissons to meet specific project needs and build them offsite to ensure quality and accuracy. -

Transportation

Tugboats or barges tow the caissons to the construction location. -

Positioning and Sinking

Crews align the caissons precisely and sink them by filling them with water or ballast to reach the target depth. -

Final Construction

Workers fill the caissons with concrete or other materials to complete the foundation. They then build piers, columns, or other structural elements inside the dry chamber.

Conclusion

Floating caissons have transformed underwater construction with their strength, efficiency, and adaptability. Their straightforward installation process, minimal environmental impact, and structural reliability make them indispensable for marine infrastructure projects. As materials and construction technologies evolve, engineers will continue to rely on floating caissons to build the bridges, ports, and offshore facilities of the future.