Laser Scanning Technology and Its Advantages in Construction Industry

10 July 2019 Off By The Engineering CommunityLaser Scanning Technology and Its Advantages in Construction Industry

Laser Scanning is a method of collecting external data using a laser scanner which captures the actual distance of densely scanned points over a given object at breakneck speed. The process is usually known as a point cloud survey or as light detection and ranging (LIDAR, a combo of the words ‘light’ and ‘radar’).

Laser scanning is currently acquiring the impetus in the construction industry for its competency in helping Building Teams to collect tons of remarkably authentic information in a very short span of time. When done in a perfect way, Laser scanning can prove to be beneficial to all the involved parties in the life cycle of the project.

The laser scanning method can be used to create 3D representations that can be converted for use in 3D CAD modeling or BIM (Building Information Modeling).

While the construction industry is relatively gradual in adopting the newer technology, the designers and the construction professionals are challenging themselves to complete the project in rapid pace with the use technologies like BIM and custom-designed apps. The 3D laser scanning is less promoted technology in the adoption phase, though the AEC industry is now noticing the benefits of laser scanning can bring the boost in their projects.

Accuracy:

The laser scanning technology determines to be much quicker, more exact and inexpensive than the traditional survey measurement. The exactness of the process depends on the stability of the instrument base and the distance from the object.

Benefits of using the Laser Scanning Technology in Construction Industry

Laser Scanning has been a boon to the construction industry that allows obtaining a level of detail, accuracy which was not feasible with the other traditional methods. Let’s have a brief look at the benefits of implementing the Laser Scanning technology to build in a smarter way.

- Enhanced Planning and Designing

Using the laser scanning method, a tremendous boost in planning and designing is seen. The clashes between newly designed elements and existing conditions have been analyzed before the construction. The exactness of dimensions obtained from laser scans can also help improve planning by providing exact measurements for destruction and removal of components as well as assist in minimizing the waste materials.

- Reduction in cost and Schedule

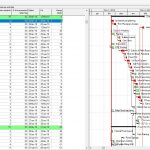

It has been seen that the 3D scanning can curtail the total project cost by 5% to 7%. The scanning can be performed in minimal hours to a few days, depending on the site as compared to several weeks in the traditional data collection methods.

- Safety and Regulatory Agreement

The Laser scanning methods are often safer that the manual data collection method and are increasingly used to help satisfy with health, safety, and environmental responsibilities. The features such as remote sensing ability and quick data capture of the laser scanner trim the teams’ exposure to harmful environments. For example, when used in nuclear power plants, the laser scanner helps in reducing the size and the time of group’s exposure to the high radiation areas.

The laser scanning provides booming methods for surveying remote surfaces as well as complex geometrical surfaces are also surveyed with absolute ease. All the major providers of CAD 3D modeling and BIM have built compatibility that acknowledges their system to import the point cloud data into the 3D visual graphic material.

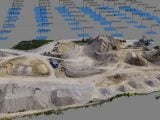

The use of drones with laser scanning has indeed become a recognized method of getting the exact detail of topography. LIDAR has been widely used for surveys from rail to the road vehicles. The instrument can easily operate at night when the targeted surfaces are less interfere with people and can produce outstanding accuracy.