Outrigger Structures Types

8 February 2020Outrigger Structures Types

1. Introduction

The concept of outrigger dates back to 50 years, it origined in deepbeams. It has been derived from deep beam into concrete walls, and now in the form of one or several story outrigger trusses.

Outriggers are one of the most widely used systems for relative regular floor plan. It is constructed using steel trusses, girders, concrete walls, or deep beams to connect the core and the columns at the perimeter.

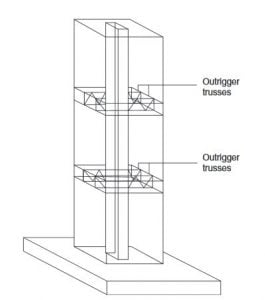

The outrigger trusses are normally one-story high, some even occupy several storys. The cores are normally located at the center of the building, whereas the outriggers extend out to the outer columns (as it is shown in Fig.1).

Therefore, the outriggers and the outer columns work together as a further restrain to the core wall. Under lateral load, the belt trusses act as lever arms that directly transfer axial stresses to the perimeter columns. The bending, axial tension, and compression of the outer columns connected to the outriggers help resist the external moments of the structure. This resistance enhances the overall stiffness of the core, helps in reducing the lateral deflections, and overturning moments.

The outrigger columns work together particularly helping to restrain the rotation of the core. Overall, major advantage of using the outrigger is to resist the rotation of the core and significantly reduce the lateral deflection and overturning moment.

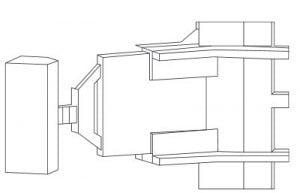

One of the famous examples of this system is Shard, London BridgeTower (Fig.2). It has core wall at the center and outrigger truss at highlevels, inside the plant room, to connect the central core and outer raking columns.

Fig.1. Outrigger structures

Fig.2. The Shard.(Adapted and reuse with the permission of Asset bank, City, Universityof London)

If the outrigger is used together with external tube systems, it can more evenly distribute the large vertical forces applied by outriggers across the multiple columns. Analysis and design of a core-and-outrigger system requires the use of computer program. This is because the distribution of forces between the core and the outrigger system are determined by the relative stiffness of eachelement: the core, the outrigger, and the columns. Therefore, it is difficult to calculate manually.

2. Types of Outriggers

There are several different types of outrigger system, such as steel outriggers, concrete outriggers, and hybrid outrigger (using both concrete and steel material). Among them, steel outriggers are most conventional type outriggers.

The famous examples are: Twin Tower (collapsed in the 9/11 attack) and the Shard in London. Concrete outriggers are used in some tall buildings. One of the famous examples is 432 Park Avenue building in NewYork.

With the development of the construction technology, new types of outriggers such as hybrid outriggers and damped outriggers have emerged in the construction projects.

2.1 Steel Outriggers

Steel outrigger systems are extensively used in a lot of tall buildings as most of tall buildings are either steel or composite structural system. In the conventional design, the outrigger is designed to be a story height truss.

2.2 Concrete Outriggers

The benefit of concrete outrigger system verses steel is high stiffness and lowcost. Under wind load cases, the outrigger system needs to be of stiff concrete deep beam or of concrete wall which can be easily achieved by this.

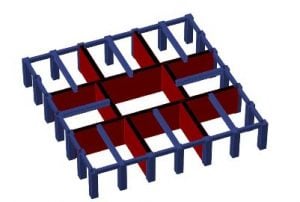

Fig. 3 shows a typical outrigger using concrete wall. This type of system is more common in a concrete structure rather than in a steel frame structure.

Fig.3. A typical outrigger using concrete wall modeled using ETABS

2.3 Hybrid Outriggers

The steel outrigger is not as stiff as concrete outrigger. However, a pure concrete outrigger system is very brittle.

An innovative type of steel-concrete hybrid outrigger truss was developed in two 370-m tall mega-high-rise towers in Raffles City Chongqing, in which the steel truss is embedded into the reinforced concrete outrigger wall as shown in Fig.4. Both the steel truss and the concrete outrigger wall work compositely t oenhance the overall structural performance of the tower structures under extreme loads.

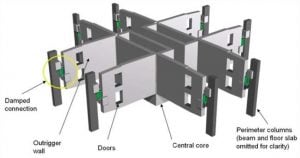

Fig.4. Fused outriggers (a concept originally developed by Arup)

2.4 Damped Outrigger

In the event of severe earthquake, the overall structural system should be able to dissipate energy and maintain its robustness against the collapse. Additional viscous dampers can be installed in the outrigger for a nonlinear response and tuned to meet multilevel performance objectives.

In case the dampers fail, the outriggers which is designed to yield in a ductile manner will remain intact. Thus, it can reduce wind-induced vibration and can also be used as fuse to protect the building under a severe earthquake condition.

Fig.5. Arup Damped Outrigger system adopted in St Francis Towers