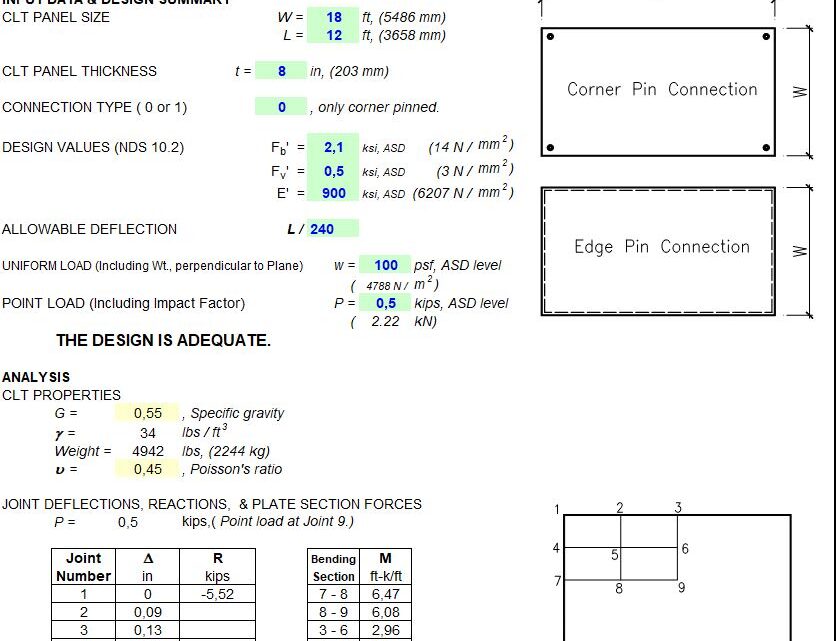

Two-way Floor Design Using Cross-Laminated Timber Spreadsheet

3 May 2025Table of Contents

Two-way Floor Design Using Cross-Laminated Timber Spreadsheet

In modern construction, sustainability and performance are no longer mutually exclusive. Two-way floor systems using Cross-Laminated Timber (CLT) offer a compelling solution that combines ecological responsibility, structural efficiency, and aesthetic appeal. As engineered timber continues to gain global traction, understanding how CLT functions in two-way spanning applications is essential for architects, engineers, and builders alike.

What is Cross-Laminated Timber (CLT)?

Cross-Laminated Timber is an engineered wood product made by stacking layers of lumber at right angles and bonding them together with structural adhesives. This cross-lamination gives the panels strength and stiffness in both directions, making CLT an ideal material for floor, wall, and roof systems.

Unlike traditional timber, CLT behaves more like concrete slabs in its ability to span large distances and resist multi-directional loads. This makes it especially suitable for two-way floor systems, where loads are transferred in both directions to the supports.

Understanding Two-Way Floor Systems

A two-way floor system is a slab or panel that distributes loads in both orthogonal directions — as opposed to a one-way system that carries loads in only one direction. In reinforced concrete, this is commonly achieved with flat slabs or waffle slabs. With CLT, achieving a true two-way action requires careful consideration of panel layout, support conditions, span ratios, and connection detailing.

How CLT Enables Two-Way Action

Although CLT panels are inherently stronger in their major direction (the direction of the outer longitudinal layers), two-way action can still be achieved under the following conditions:

-

Square or near-square panels: Panels with aspect ratios close to 1:1 enable more balanced load distribution.

-

Continuous support on all four edges: A prerequisite for effective two-way load transfer.

-

Use of thicker or specially engineered panels: Additional lamellae or hybrid CLT panels can enhance strength in both directions.

-

Mechanical reinforcement: Integrating steel plates or screws to increase interlaminar strength can support two-way action.

Design Considerations for CLT Two-Way Floors

To design effective two-way CLT floor systems, engineers must account for:

1. Span-to-Depth Ratio

A typical CLT floor has a span-to-depth ratio between 18 and 25. For two-way designs, the goal is to keep both spans within a close range and optimize panel thickness accordingly.

2. Support Conditions

True two-way behavior depends heavily on continuous or fixed edge support. Cantilever or simply-supported edges reduce two-way capacity.

3. Connection Detailing

Proper edge and corner connections are critical. Custom hardware or embedded plates can be used to ensure effective force transfer between adjacent panels and supports.

4. Vibration Control

Due to its lightweight nature, CLT is more susceptible to vibration. Two-way action can help distribute dynamic loads more evenly, but designers must still check natural frequency and acceleration limits per standards like ISO 10137 or CSA O86.

5. Fire and Acoustic Performance

CLT offers inherent fire resistance due to its charring behavior, and two-way systems can help compartmentalize fire zones. For acoustics, consider topping layers or resilient connections to reduce impact and airborne noise.

Advantages of Two-Way CLT Floor Systems

-

Increased load-sharing capacity: Better structural efficiency compared to one-way systems.

-

Material savings: Reduced need for beams or joists in mid-spans.

-

Architectural flexibility: Exposed timber surfaces create a warm, natural aesthetic.

-

Environmental benefit: Lower embodied carbon than concrete or steel systems.

-

Prefabrication: CLT panels are manufactured off-site, ensuring precision and reducing on-site waste.