What is a Highway Impact Attenuator?

2 July 2021 Off By The Engineering CommunityWhat is a Highway Impact Attenuator?

Highway impact attenuators are devices which are generally used to reduce the impact resulting from a motor vehicle collision, where those impacts might damage other vehicles, motorists, or structures nearby.

In some cases, they are also designed to redirect a colliding vehicle away from roadway machinery, workers, or some other fixed structure. Impact attenuators be classified into three distinct categories, which are based on the engineering method which is used to reduce the kinetic energy of a colliding automobile.

Impact Attenuator Categories:

Momentum transfer, in which the impacting vehicle’s momentum is transferred to containers having sand or water in them, thereby successively lowering the speed of a colliding vehicle.

Material deformation, this category uses crushable materials which absorb energy by creating a crumple zone.

Friction: these work by causing a steel cable to be pushed through an angled slot, thereby transforming kinetic energy into harmless heat.

Impact Attenuator Types:

There are several types, and most of these can be frequently seen along roadsides at locations where it is necessary to protect those kinds of objects and individuals.

Crash cushions:

These attenuators are constructed of several segments, all of which crumple into each other when struck by a colliding automobile, and these are often used because of their reusable nature.

After being struck by a colliding vehicle, they can return to their original form and can be used again. Fitch barriers are sand-filled plastic containers, most often colored yellow with a black lid.

They are generally set up in a triangular arrangement between a highway and an exit line, also known as the gore point, and always along the most likely collision line.

The containers which are most forward usually have the least amount of sand in them, with each successive barrel having a higher level of sand.

This allows an impacting vehicle to decelerate more or less smoothly, rather than striking a solid obstruction in a violent manner.

Crash cushions are often implemented along the shoulders of a roadway where it is necessary to protect against collisions with the hazard directly behind them. They can be ground-mounted or surface-mounted and situated on top of a concrete pad.

Water-filled impact attenuators:

They are filled with water which absorbs the force of a colliding auto. Since these are not anchored to the ground, they can easily be redeployed to locations where they are needed.

The water in the containers helps absorb all the kinetic energy so that there is less damage to objects behind the containers, and to the occupants of the colliding vehicle. In cold climates, when water-filled options are used, it will be necessary to include an additive such as magnesium chloride to prevent them from freezing.

Gating impact attenuators:

They permit vehicles that collide with them from the side, to pass right through, and are often used because they’re so economical. However, they do require more clearing space around them in order to be effective, because, without sufficient space, it might be possible for an impacting automobile to pass through and collide with another hazard.

Non-gating impact attenuators:

They do stop the motion of head-on impacts, but also deflect vehicles which strike the sides of the barrier. These types are more expensive because they are anchored, but they require less space than gating versions.

Fitch barriers:

They are most often used at temporary construction worksites, for example at the end of a concrete barrier. They are also used at bridge piers, wide medians, and for two-sided protection.

Where are These Cushions Placed?

Highway impact attenuators are often placed forward of objects along the freeway such as overpass supports, crash barrier introduction, and gore points.

They are frequently used at the side of road construction projects, where there is a greater likelihood of collision with construction equipment and or individuals. Truck-mounted versions is another type which are deployed on vehicles that happen to be susceptible to being hit from behind, for example, maintenance vehicles, road construction vehicles, and snowplows.

More from my site

Wind Design For Rooftop Solar Panels Based on ASCE 7-16 Spreadsheet

Wind Design For Rooftop Solar Panels Based on ASCE 7-16 Spreadsheet Deep Thrust Block For Pressured Bend Pipe Buried In Soil Spreadsheet

Deep Thrust Block For Pressured Bend Pipe Buried In Soil Spreadsheet Bridge ABUTMENT DESIGN EXAMPLE

Bridge ABUTMENT DESIGN EXAMPLE Tube – Pipe Column Design Spreadsheet

Tube – Pipe Column Design Spreadsheet Minaret Details Autocad Free Drawing

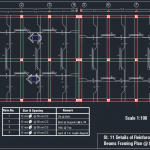

Minaret Details Autocad Free Drawing Details of Reinforcement and Beams Framing Plan Autocad Drawing

Details of Reinforcement and Beams Framing Plan Autocad Drawing