What Is Vibrator? Types Of Vibrators Used In Construction

12 December 2021Table of Contents

What Is Vibrator? Types Of Vibrators Used In Construction

Introduction

Vibrators are used to compact concrete on the construction site. They are available in a wide range of shapes and sizes. Some Concrete Vibrators are smaller, more efficient, and run on battery power, while others are much larger and rely on electric power.

In the event of vibration, compacting is caused by a reduction in internal friction between various concrete particles due to particle oscillation, resulting in a dense and compact concrete mass.

It is primarily utilized in the construction of roads, trains, and buildings for concrete compaction. It compacts newly poured concrete by removing trapped air and excess moisture. Its purpose is to secure the concrete in the formwork.

This is done to ensure correct concrete consolidation and prevent product faults. These vibrators can have vibration frequencies ranging from 2800 to 15000 rpm.

Types Of Vibrators Used In Construction

1. Internal Vibrators

Internal. vibrators, also known as immersion or concrete needle vibrators are the most common types of vibrators used on construction sites.

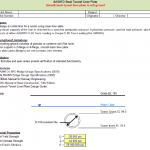

It comprises a steel tube with an eccentric vibrating element within (one end closed and rounded). The poker vibrator machine comprises a steel tube connected to an electric motor, a diesel engine, or a gasoline engine via a flexible tube.

The size of poker ranges from 40 to 100 mm in diameter. The poker diameter is determined by taking into account the distance between the reinforcing bars in the formwork.

Internal vibrator machine’s needle sizes range from 25 mm to 90 mm, with a minimum of 25 mm and a maximum of 35 mm used for roof slab casting.

For the compaction of concrete mass in column and beam structures, we should utilize a vibrator machine with 40 mm and 60 mm needles.

When proposing a strong footing and various bridge structures, we should use a vibrator machine with a 75 mm and 90 mm needle to compact the concrete mass by capturing air gaps and preventing honeycomb.

Vibrations from vibrator machines have a frequency of up to 15000 rpm. However, with an accel, a range of 3000 to 6000 rpm is advised as a preferable minimum.

2. External Vibrator

These vibrators are clamped rigidly to the form work at the pre-determined points so that the form and concrete are vibrated. They consume more power for a given compaction effect than internal vibrators.

The external vibrator is also known as shutter shape vibrator. It includes a base plate. It is used to compact the surface of precast concrete as well as the freshly poured concrete. A three-phase induction motor powers it.

Its construction is completely dosed. It’s also trustworthy and easy to maintain, with a power cord made up of four rubber-coated cables. The casing is usually built of an aluminum alloy casting. It has a highly efficient lightweight motor structure.

According to the building pattern, the machine is secured to the formwork horizontally or vertically at acceptable spacing but not exceeding 90 cm in both directions.

3. Surface Vibrator

Surface vibrators are permanently affixed to the concrete mass. During the screening process, they vibrate the concrete away from the surface.

When used in conjunction with concrete with low water to cement ratio, it is an excellent choice for the compaction of shallow elements.

For greater depth than 250 mm of the concrete, we should not use it. With the help of this machine, even dry mixes can be compacted successfully. Surface vibrators include things like pan vibrators and vibrating screeds.

It is commonly used for compacting small slabs, mending, and fixing horizontal. surfaces such as pavement stabs. It spins at a frequency of around 4000 rpm.

4. Vibrating Table

Although the formwork is clamped to the vibrator, the principle of vibrating the concrete and formwork remains unchanged. The vibration flavor is also comparable.

A fast-spinning eccentric weight, in general, produces In a circular motion, the table vibrates. The system is made up of two shafts that rotate in opposite directions.

The table can be subjected to a horizontal component of vibration that can be neutralized. Only in the vertical direction is there a simple harmonic motion.

There are also some minor positives. Vibrating tables of high quality powered by an electromagnet powered by alternating current. The frequency range reached is between 1,500 and 7000 rpm.

A table with variable amplitude should be utilized for vibrating concrete sections of various diameters or laboratory purposes. Vibrations with varying frequencies are a bonus. A vibrating table is a safe and effective way of compacting precast concrete.

The benefit of providing consistent treatment electrically or pneumatically controlled vibrating tables is particularly beneficial for precasting work.

The vibrating tables are very efficient in compacting stiff and harsh concrete mixes required for manufacture of precast elements in the factories and test specimens in laboratories.